@kwilford..... Any updates on your end?

Patience, Grasshopper....

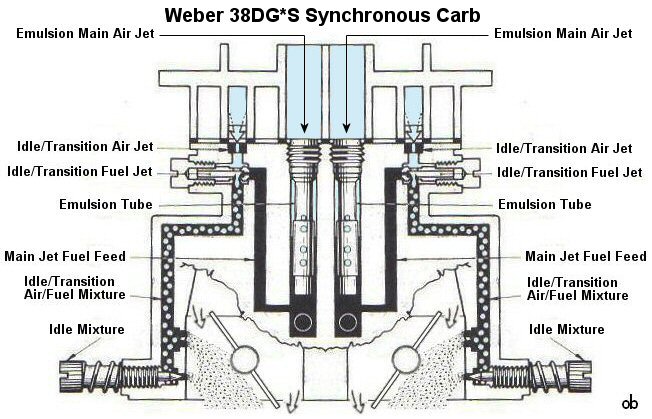

Yes, re-jetting a Weber is like a marshal art. And I missed all those Kung Fu classes.

On top of re-jetting the Weber 38DGES, I have also been making adjustments to the distributor mechanical advance. To recap, it is a '75 dizzy, has a locked vacuum plate (no retard pot, never had an advance that year) and has adjustable mechanical advance using set screws. Pertronix II Ignitor and FlameThrower coil (but the 3 ohm unit, as I started with a Pertronix I that Sterling needed more than me). The advance target is 12 to 15 degrees BTDC at 1000 rpm idle, maxing at 36 degrees at ~3500 rpm.

I am "pretty" happy with the current tune, so I took my GT out on its very first long'ish road trip yesterday, totaling 180 km (112 miles). It was a good mix of highway and city driving, from my house in NW Calgary, down to John Warga's acreage (the Calgary Opel Parts Co-Op storage) south of the city, to drop off and pick up some co-op parts. Then to Tom Bradshaw's (not sure of his user name here) to see his progress in dismantling his teal-green GT (some photos attached) and drop some co-op parts off, then all the way Vince Tucker's place to see his GT re-assembly (forgot to take photos) and back home. Odometer was accurate to within 1 km of 180 as tracked by my Garmin GPS, but my NOS zero km Euro speedometer reads about 9% high. Might prevent a few speeding tickets. Maximum speed attained was 128 km/hr (~80 mph) so I still need to watch my right foot. Car ran very well, except for a slightly leaky heater valve ( a fancy thermo-controlled NOS unit, but hey, likely 30 years old) which will be replaced with an OGTS valve loaned to me by Vince.

Here is a copy and paste from the notes I have been making along the path to Weber and distributor advance enlightenment. Its a bit wordy, but what you guys might expect from me.

Revised jets: 2020-04-05 a)

Venturi's: 3.5 (w/ brass cross tubes)

Pump jet: 60 (double)

Emulsion tubes: F66 (both sides)

Main jets: 135 (both sides)

Air correctors: 160 (both sides)

Idle jets: 45 (from 40's, both sides) best at 1 3/4 turns inboard, 2 3/4 turns outboard (adjusted w/ vacuum gauge)

Idle 1000 rpm: 12.3:1

2000 rpm: 13.7:1

3000 rpm: 15.3:1

4000 rpm: 15.4:1

4500 rpm: 15.2:1

Too lean thu-out, stumble off idle, idle uneven

Tried 50 i/b idle jet, best at 2 turns, idle AFR improved to 12.1:1 but still too lean throughout

Revised jets: 2020-04-05 b)

Main jets: 140 (from 135, both sides)

Air correctors: still 160 (both sides)

Idle jets: same 45 o/b, 50 i/b, best at 2 turns inboard, 3 turns outboard (adjusted w/ vacuum gauge)

Idle 1000 rpm: 12.6:1

2000 rpm: 13.9:1

3000 rpm: 14.8:1

4000 rpm: 13.9:1

4500 rpm: 13.9:1

Road test 2020-04-30:

1000 rpm 17 deg, 12.0:1

2000 rpm 27 deg, 13.5:1

3000 rpm 35 deg, 14.0:1 & too lean

3500 rpm 36 deg, 14.5.1 & too lean

Stumble off-idle tip in

13.0:1 at 100 km/hr (2500 rpm) cruise

Good power, but doesn't pull strongly above 3000 rpm

Intermittent 15.0:1 lean when accelerating

Revised jets: 2020-04-30

Main jets: 145 (from 140, both sides)

Air correctors: 170 (from 160, both sides)

Idle jets: 50 o/b, 50 i/b, best at 2 1/2 turns inboard, 2 1/2 turns outboard (adjusted w/ vacuum gauge)

Idle 1000 rpm: 12.5 to 13.2:1

2000 rpm: 14.6:1

3000 rpm: 15.1:1

4000 rpm: 16.0:1 and lean

4500 rpm: 13.5:1

Road test:

Idles better but not great after turning screws out, AFR still too lean; fair to good power, AFR 14.5:1 at 100 km/hr (2500 rpm) cruise, richer under acceleration, too lean at mid-range

2020-05-02

Re-locked vacuum plate at advanced position (was retarded)

900 rpm: 12 deg, 12.0-13.0:1, 11"Hg

1000 rpm: 20 deg, 11.5-12.5:1, 13" Hg

2000 rpm: 23 deg, 12.2-13.1:1, 18" Hg

3000 rpm: 35 deg, 13.3-13.6:1, 21" Hg

3500 rpm: 36 deg, 13.5-14.1:1, 20" Hg

Main jets: 150 IB/155 OB (from 145 both sides)

Air correctors: 180/180 (from 170's)

Idles: still 50/50, best at 2 turns IB, 2 1/4 turns OB

Installed Bosch Platinum WR7BP plugs

1000 rpm: 12.6-12.8:1, 16 deg.

2000 rpm: 13.1-13.5:1, 22 deg

3000 rpm: 14.0 to TOO LEAN, 35 deg

3500 rpm: 13.5-14.2:1, 35 deg

Intermittent stumble on tip in, good power thru band, lean at 3500 rpm under power

2020-05-05

Main jets: 155/155 (was 150/155)

Air correctors: 175 IB, 180 OB (was 180/180)

Idles: still 50/50, best at X turns IB, X turns OB

1000 rpm: 11.8-12.5:1

2000 rpm: 12.9-13.1:1

3000 rpm: 14.0-TOO LEAN

3500 rpm: 13.2-13.8:1

4000 rpm: 13.0-13.2:1

4500 rpm: 12.4-12.8:1

Pulls strong from 3000 to 5000 rpm, still leans out at 3000 to 3500 rpm under load, but no stumble

2500 rpm, 5th gear, 110 km/hr, 13.5-15.0:1

3200 rpm, 4th gear, 110 km/hr, 13.4-14.5:1

4100 rpm, 3rd gear, 100 km/hr, 14.5- 15.0:1

It surprises me that I am running such large main jets, at 155 both sides. Bob's suggestion is to run the air correctors 30 to 40 larger than the mains, less at higher altitude (I live at 3000 ft ASL), but I am running only 20 and 25 respectively to make the mid and high rpm AFR rich enough without over-fueling.

I'll pull the spark plugs (Bosch Platinum) tomorrow to see what they tell me, but the Champion plugs that came out a week ago looked almost perfect, with a couple hundred km on them.

Likely not the absolute final set up, but good enough for now.

HTH